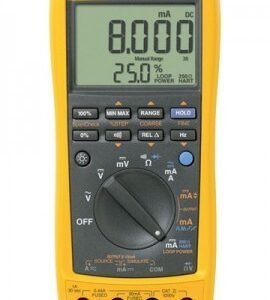

Uses Field-Sense™ technology to make testing faster and safer, all without touching a live conductor, and provides accurate voltage and current measurements through the clamp jaw. Easily clip the black test lead to any electrical ground, put the clamp jaw around the conductor, and see reliable, accurate voltage and current values on the display.

Features

Measure voltage and current with your clamp jaw

Faster, safer testing all without touching a live wire using FieldSense™ technology

Complete three-phase voltage and current tests in three quick steps

Voltage and current measurements with FieldSense™ technology

No more hand-written notes or complicated math.

Complete 3-phase voltage and current tests in three easy steps

Full set of phase-to-ground and phase-to-phase values calculated

Displayed on your smart phone and saved to the cloud via Fluke Connect software

Phase rotation calculated and shown on the Fluke Connect software

Measure extremely high current with iFlex™ probe

Use the included iFlex flexible current probe to measure ac current as high as 2500 A. The iFlex probe provides access to large conductors in tight spaces.

Easy to see, easy to use with included tools

Your job will get easier when you use this clamp meter:

The display turns green when a stable FieldSense measurement is detected

Visual Continuity provides a bright green screen for easy detection of continuity in noisy work areas

The magnetic hanging kit, with 9″ (23 cm) hanging strap, lets you hang your clamp wherever you need: to a steel cabinet door; around a pipe; on a nail or screw head

Record, analyze, share results with Fluke Connect™ software

With Fluke Connect software you can remotely log, trend and monitor measurements to pinpoint intermittent faults. Fluke Connect also allows

you to gather data as the basis for a preventive maintenance program.

Applications

Electrical

HVAC/R

Field service

Maintenance

Solving Electrical Problems with Fluke Thermal Imaging

Today’s thermal imagers have become a realistic solution for everyday electrical maintenance as they are rugged, easy to use, and much more affordable than even just a few years ago. It’s a straight-forward process, where a qualified technician or electrician points the thermal imager at the equipment in question and scans the immediate area, looking for unexpected hot spots. The imager produces a live image of the heat emitted from the equipment and with the quick squeeze of the trigger, a thermal image is captured. When the inspection is complete, the image is uploaded to a computer, Apple®, iPhone® or iPad® for closer analysis, reporting, and future trending.

There are a few basic how-tos to consider… electrical load, safety, and emissivity. In this application note, we walk you through these, as well as the Top 5 Checklist, and much more.

Read the Application Note

Using Fluke Thermal Imaging to Troubleshoot Motors & Drives

Infrared cameras, also called thermal imagers, are useful for troubleshooting motor problems as well as for monitoring motor condition for preventative maintenance in power generation, manufacturing and commercial plants. Thermal images of motors reveal their operating condition as indicated by surface temperature. Such condition monitoring is important as a way to avert many unexpected motor malfunctions in systems that are critical to manufacturing. The onset of motor failures can often be detected by a variety of techniques, including vibration, ultrasound and thermal imaging.

In this article, we cover why use thermal imaging and what to scan, as well as some notes on what to look for, including shaft misalignment.

Read the Article

Facilities Maintenance Challenges and the Fluke Solutions

Facilities maintenance professionals face a wide range of challenges, from electrical and mechanical equipment uptime to overall safety concerns. It’s critical to maintain facilities and the associated assets at peak performance. Let’s review the issues faced by maintenance managers, IT support, and electrical/mechanical technicians. Along with the Fluke solutions that offer to save you time and money while increasing efficiency and safety. Fluke makes reliable, rugged and accurate tools to maintain electromechanical systems, motors, pumps, electrical distribution systems and more to keep your world up and running.

Learn MoreUses Field-Sense™ technology to make testing faster and safer, all without touching a live conductor, and provides accurate voltage and current measurements through the clamp jaw. Easily clip the black test lead to any electrical ground, put the clamp jaw around the conductor, and see reliable, accurate voltage and current values on the display.

Features

Measure voltage and current with your clamp jaw

Faster, safer testing all without touching a live wire using FieldSense™ technology

Complete three-phase voltage and current tests in three quick steps

Voltage and current measurements with FieldSense™ technology

No more hand-written notes or complicated math.

Complete 3-phase voltage and current tests in three easy steps

Full set of phase-to-ground and phase-to-phase values calculated

Displayed on your smart phone and saved to the cloud via Fluke Connect software

Phase rotation calculated and shown on the Fluke Connect software

Measure extremely high current with iFlex™ probe

Use the included iFlex flexible current probe to measure ac current as high as 2500 A. The iFlex probe provides access to large conductors in tight spaces.

Easy to see, easy to use with included tools

Your job will get easier when you use this clamp meter:

The display turns green when a stable FieldSense measurement is detected

Visual Continuity provides a bright green screen for easy detection of continuity in noisy work areas

The magnetic hanging kit, with 9″ (23 cm) hanging strap, lets you hang your clamp wherever you need: to a steel cabinet door; around a pipe; on a nail or screw head

Record, analyze, share results with Fluke Connect™ software

With Fluke Connect software you can remotely log, trend and monitor measurements to pinpoint intermittent faults. Fluke Connect also allows

you to gather data as the basis for a preventive maintenance program.

Applications

Electrical

HVAC/R

Field service

Maintenance

Solving Electrical Problems with Fluke Thermal Imaging

Today’s thermal imagers have become a realistic solution for everyday electrical maintenance as they are rugged, easy to use, and much more affordable than even just a few years ago. It’s a straight-forward process, where a qualified technician or electrician points the thermal imager at the equipment in question and scans the immediate area, looking for unexpected hot spots. The imager produces a live image of the heat emitted from the equipment and with the quick squeeze of the trigger, a thermal image is captured. When the inspection is complete, the image is uploaded to a computer, Apple®, iPhone® or iPad® for closer analysis, reporting, and future trending.

There are a few basic how-tos to consider… electrical load, safety, and emissivity. In this application note, we walk you through these, as well as the Top 5 Checklist, and much more.

Read the Application Note

Using Fluke Thermal Imaging to Troubleshoot Motors & Drives

Infrared cameras, also called thermal imagers, are useful for troubleshooting motor problems as well as for monitoring motor condition for preventative maintenance in power generation, manufacturing and commercial plants. Thermal images of motors reveal their operating condition as indicated by surface temperature. Such condition monitoring is important as a way to avert many unexpected motor malfunctions in systems that are critical to manufacturing. The onset of motor failures can often be detected by a variety of techniques, including vibration, ultrasound and thermal imaging.

In this article, we cover why use thermal imaging and what to scan, as well as some notes on what to look for, including shaft misalignment.

Read the Article

Facilities Maintenance Challenges and the Fluke Solutions

Facilities maintenance professionals face a wide range of challenges, from electrical and mechanical equipment uptime to overall safety concerns. It’s critical to maintain facilities and the associated assets at peak performance. Let’s review the issues faced by maintenance managers, IT support, and electrical/mechanical technicians. Along with the Fluke solutions that offer to save you time and money while increasing efficiency and safety. Fluke makes reliable, rugged and accurate tools to maintain electromechanical systems, motors, pumps, electrical distribution systems and more to keep your world up and running.

Learn More

Fluke 377FC Specifications

Current

AC – Jaw

Range: 999.9 A

Resolution: 0.1 A

Accuracy: 2% ±5 digits (10 to 100 Hz); 2.5% ±5 digits (100 to 500 Hz)

Crest factor (50/60 Hz): 3 at 500 A; 2.5 at 600 A; 1.42 at 1000 A; Add 2% for C.F. >2

AC – Flexible Current Probe

Range: 2500 A

Resolution: 1 A (≤2500 A) 0.1 A (≤999.9 A)

Accuracy: 3% ±5 digits (5 to 500 Hz)

DC

Range: 999.9 A

Resolution: 0.1 A

Accuracy: 2% ±5 digits

Voltage

AC – FieldSense

Range: 1000 V

Resolution: 1 V (≤1000 V)

Accuracy: ≤4/0 AWG – 3% ±5 digits (45 to 66 Hz); ≥4/0 AWG – 5% ±5 digits (45 to 66 Hz)

AC – Test Leads

Range: 600.0 V, 1000 V

Resolution: 0.1 V (≤600.0 V); 1 V (≤1000 V)

Accuracy: 1% ±5 digits (20 to 500 Hz)

DC

Range: 600 V, 1000 V

Resolution: 0.1 V (≤600 V); 1 V (≤1000 V)

Accuracy: 1% ± 5 digits

mV DC

Range: 500 mV

Resolution: 0.1 mV

Accuracy: 1% ±5 digits

Amps Frequency

Jaw

Range: 5 to 500 Hz

Resolution: 0.1 Hz

Accuracy: 0.5% ±5 digits

Trigger level: 5 to 10 Hz, ≥10 A; 10 to 100 Hz, ≥5 A; 100 to 500 Hz, ≥10 A

Flexible Current Probe

Range: 5 to 500 Hz

Resolution: 0.1 Hz

Accuracy: 0.5% ±5 digits

Trigger level: 5 to 20 Hz, ≥25 A; 20 to 100 Hz, ≥20 A; 100 to 500 Hz, ≥25 A

Other Measurements

Resistance

Range: 60 kΩ, 6000 Ω, 600 Ω

Resolution: 0.1 Ω (≤600 Ω), 1 Ω (≤6000 Ω), 10 Ω (≤60 kΩ)

Accuracy: 1% ±5 digits

Capacitance

Range: 1000 μF

Resolution: 0.1 μF (≤100 μF), 1 F (≤1000 μF)

Accuracy: 1% ±4 digits

General Specifications

General Maximum Voltage

1000 V (between any terminal and earth ground)

Battery

Type: 2 x AA IEC LR6 alkaline

life: 200 hours

Display

Dual readout

Automatic Power Off

20 minutes

Temperature

Operating: 14 to 122°F (-10 to 50°C)

Storage: -40 to 140°F (-40 to 60°C)

Operating Humidity (Without Condensation)

Non condensing (<50°F [<10°C])≤90% RH (50 to 86°F [10 to 30°C])≤75% RH (86 to 104°F [30 to 40°C])≤45% RH (104 to 122°F [40 to 50°C])

Temperature Coefficients

Add 0.1 x specified accuracy for each degree C >28°C or <18°C

Ingress Protection

IEC 60529: IP30 (jaw closed)

Altitude

Operating: 6561.68' (2000 m)Storage: 39,370.1' (12,000 m)

Electromagnetic Compatibility (EMC)

USA (FCC): 47 CFR 15 subpart B. This product is considered an exempt device per clause 15.103

Safety

General: IEC 61010-1: Pollution degree 2Measurement: IEC 61010-2-032: CAT III 1000 V/CAT IV 600 V; IEC 61010-2-033: CAT III 1000 V/CAT IV 600 V

Wireless Radio

Radio frequency certification: FCC ID: T68-FBLE IC:6627A-FBLEFrequency range: 2405 to 2480 MHzOutput power: <100 mW

Dimensions

10.78 x 3.38 x 1.85" (274 x 86 x 47 mm)Jaw opening: 1.34" (34 mm)Flexible current probe diameter: 0.29" (7.5 mm)Flexible current probe cable length: 5.9' (1.8 m)Rogowski coil length: 17.71" (450 mm)

Weight

1 lbs (463 g) with batteries

Click here for complete specifications on the Fluke 377FC

What's included with the Fluke 377FC

Clamp Meter

Flexible Probe

ToolPak™ Magnetic Meter Hanger

Test Leads

TwistGuard™ Test Probes

Black Grounding Clip

Premium Carrying Case

Quick Reference Guide

There are no reviews yet.